What Does it Take to Be an Industrial Engineer?

Industrial Engineer Definition Design, develop, test, and evaluate integrated systems for managing industrial production processes, including human work factors, quality control, inventory control, logistics and material flow, cost analysis, and production coordination.

Industrial Engineer Responsibilities

- Draft and design layout of equipment, materials, and workspace to illustrate maximum efficiency using drafting tools and computer.

- Formulate sampling procedures and designs and develop forms and instructions for recording, evaluating, and reporting quality and reliability data.

- Plan and establish sequence of operations to fabricate and assemble parts or products and to promote efficient utilization.

- Develop manufacturing methods, labor utilization standards, and cost analysis systems to promote efficient staff and facility utilization.

- Confer with clients, vendors, staff, and management personnel regarding purchases, product and production specifications, manufacturing capabilities, or project status.

- Analyze statistical data and product specifications to determine standards and establish quality and reliability objectives of finished product.

Featured schools near , edit

Industrial Engineer Needed Skills

These are the skills Industrial Engineers say are the most useful in their careers:

Reading Comprehension: Understanding written sentences and paragraphs in work related documents.

Complex Problem Solving: Identifying complex problems and reviewing related information to develop and evaluate options and implement solutions.

Active Listening: Giving full attention to what other people are saying, taking time to understand the points being made, asking questions as appropriate, and not interrupting at inappropriate times.

Writing: Communicating effectively in writing as appropriate for the needs of the audience.

Critical Thinking: Using logic and reasoning to identify the strengths and weaknesses of alternative solutions, conclusions or approaches to problems.

Speaking: Talking to others to convey information effectively.

Related Job Titles

- Production Engineer

- Supplier Quality Engineer (SQE)

- Packaging Engineer

- Tool Engineer

- Environmental Systems Coordinator

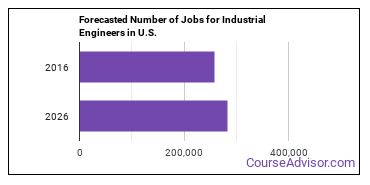

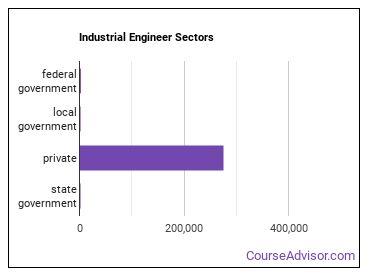

Industrial Engineer Employment Estimates

There were about 257,900 jobs for Industrial Engineer in 2016 (in the United States). New jobs are being produced at a rate of 9.7% which is above the national average. The Bureau of Labor Statistics predicts 25,100 new jobs for Industrial Engineer by 2026. Due to new job openings and attrition, there will be an average of 19,700 job openings in this field each year.

The states with the most job growth for Industrial Engineer are Nevada, Utah, and Alabama. Watch out if you plan on working in New Mexico, Vermont, or Maryland. These states have the worst job growth for this type of profession.

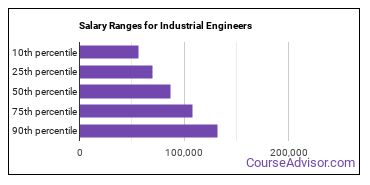

How Much Does an Industrial Engineer Make?

The salary for Industrial Engineers ranges between about $56,470 and $132,340 a year.

Industrial Engineers who work in Wyoming, Washington, or Texas, make the highest salaries.

How much do Industrial Engineers make in each U.S. state?

| State | Annual Mean Salary |

|---|---|

| Alabama | $87,870 |

| Arizona | $95,940 |

| Arkansas | $77,100 |

| California | $107,810 |

| Colorado | $100,460 |

| Connecticut | $89,830 |

| Delaware | $94,590 |

| District of Columbia | $88,380 |

| Florida | $77,410 |

| Georgia | $86,220 |

| Hawaii | $95,590 |

| Idaho | $94,830 |

| Illinois | $88,850 |

| Indiana | $74,430 |

| Iowa | $82,770 |

| Kansas | $79,580 |

| Kentucky | $79,170 |

| Louisiana | $99,090 |

| Maine | $88,020 |

| Maryland | $102,200 |

| Massachusetts | $102,210 |

| Michigan | $89,330 |

| Minnesota | $90,580 |

| Mississippi | $82,040 |

| Missouri | $87,620 |

| Montana | $100,640 |

| Nebraska | $85,950 |

| Nevada | $87,140 |

| New Hampshire | $91,530 |

| New Jersey | $98,050 |

| New Mexico | $102,120 |

| New York | $94,700 |

| North Carolina | $87,110 |

| North Dakota | $79,980 |

| Ohio | $84,060 |

| Oklahoma | $85,280 |

| Oregon | $90,980 |

| Pennsylvania | $86,080 |

| Rhode Island | $97,610 |

| South Carolina | $87,080 |

| South Dakota | $82,780 |

| Tennessee | $84,070 |

| Texas | $109,880 |

| Utah | $89,830 |

| Vermont | $79,700 |

| Virginia | $93,980 |

| Washington | $106,980 |

| West Virginia | $94,480 |

| Wisconsin | $77,260 |

| Wyoming | $102,730 |

What Tools do Industrial Engineers Use?

Although they’re not necessarily needed for all jobs, the following technologies are used by many Industrial Engineers:

- Microsoft Excel

- Microsoft Word

- Microsoft Office

- Microsoft PowerPoint

- Python

- Microsoft Access

- Data entry software

- SAP

- Microsoft Project

- Autodesk AutoCAD

- Microsoft SharePoint

- Microsoft Visio

- Structured query language SQL

- The MathWorks MATLAB

- SAS

- Linux

- IBM Notes

- Microsoft Visual Basic

- Extensible markup language XML

- Microsoft SQL Server

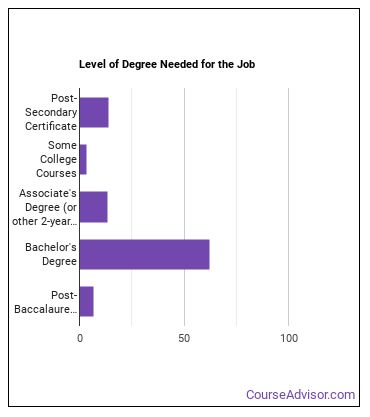

How to Become an Industrial Engineer

Education needed to be an Industrial Engineer:

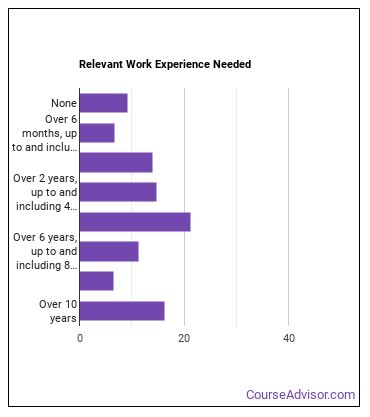

What work experience do I need to become an Industrial Engineer?

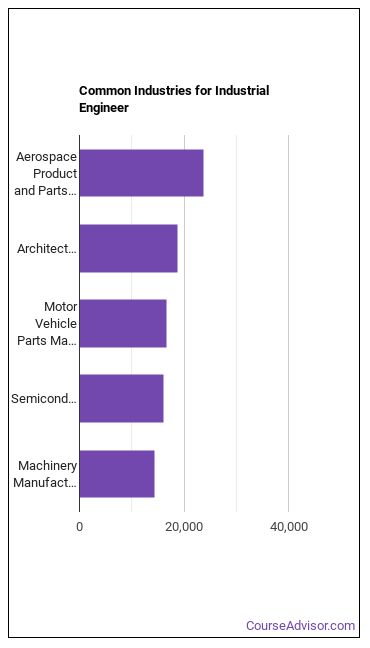

Where do Industrial Engineers Work?

The table below shows some of the most common industries where those employed in this career field work.

Other Jobs You May be Interested In

Those interested in being an Industrial Engineer may also be interested in:

Those who work as an Industrial Engineer sometimes switch careers to one of these choices:

- Logistics Engineers

- Product Safety Engineers

- Electronics Engineers, Except Computer

- Architectural and Engineering Managers

- Robotics Engineers

References:

Image Credit:

More about our data sources and methodologies.

Featured Schools

Request Info

Request Info

|

Southern New Hampshire University You have goals. Southern New Hampshire University can help you get there. Whether you need a bachelor's degree to get into a career or want a master's degree to move up in your current career, SNHU has an online program for you. Find your degree from over 200 online programs. Learn More > |